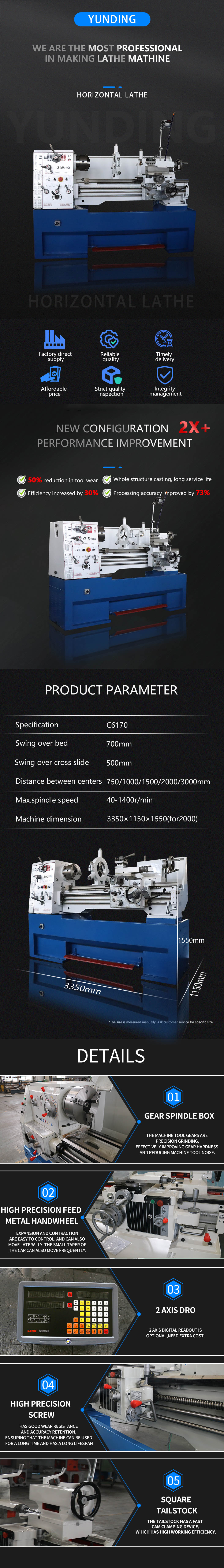

C6170

This machine is widely used for processing electrical appliances, instruments, automobiles, motorcycles, fasteners, bearings, photographic and movie machinery, hardware tools, watches, eyeglasses, stationery motors, valves, gas piping and other high-precision and complex components. It is an ideal and efficient equipment

This machine is widely used for processing electrical appliances, instruments, automobiles, motorcycles, fasteners, bearings, photographic and movie machinery, hardware tools, watches, eyeglasses, stationery motors, valves, gas piping and other high-precision and complex components. It is an ideal and efficient equipment

Product Use:

This machine is widely used for processing electrical appliances, instruments, automobiles, motorcycles, fasteners, bearings, photographic and movie machinery, hardware tools, watches, eyeglasses, stationery motors, valves, gas piping and other high-precision and complex components. It is an ideal and efficient equipment

Performance characteristics:

After hardening hard gears, precision grinding

Intermediate frequency quenching treatment of the rail surface

Dynamic balance spindle components

Multiple choices: metric, imperial, right handwheel, multiple voltage frequencies, guards with "CE" requirements, fast forward

Machine tools will be strictly inspected before leaving the factory. After the inspectors use the equipment to test, the head of the quality control team will then review it. After each index is qualified, it will be allowed to leave the factory.Standard accessories

3-jaw chuck

center¢re sleeve

wrenches、oil gun

operation manual

Optional accessories

Follower rest

4-jaw chuck

Face plate

Thread chasing dial

Longitudinal automatic trip

Live center

Quick change toolpost

Taper copy ruler

4-position longitudinal trip

Product Parameters

| Specifications | C6170 | ||

| Capacity | Max. swing over bed | 700mm | |

| Max.swing over cross slide | 500mm | ||

| Center distance | 750,1000,1500,2000mm | ||

| Spindle hole | 52mm(82mm) | ||

| Spindle | Spindle nose | ISO-C6(C8) | |

| Spindle tap | MT6 | ||

| Spindle speeds(Number) | 40-1400rpm (9 Steps) | ||

| Feed | Metric threads range(Kinds) | 0.5-14mm (20 Kinds) | |

| Inch threads range(Kinds) | 2-40/inch (28 Kinds) | ||

| Module threads range(Kinds) | 0.25-3.55mπ (11 Kinds) | ||

| Compound rest travel | 150mm | ||

| Cross slide travel | 180mm | ||

| Cross-section size of tool shank | 20×20mm2 | ||

| Tailstock | Dia. of tailstock sleeve | 65mm | |

| Taper of tailstock sleeve | MT5 | ||

| Travel of tailstock sleeve | 140mm | ||

| Main motor power | 7.5KW | ||

| Machine size(L*W*H mm) | Overall dimensions for750mm | 2100×1150×1550mm | |

| Overall dimensions for1000mm | 2350×1150×1550mm | ||

| Overall dimensions for1500mm | 2850×1150×1550mm | ||

| Overall dimensions for2000mm | 3350×1150×1550mm | ||

| Weight(kg) | Weight for 750mm | 1900kg | |

| Weight for 1000mm | 2000kg | ||

| Weight for 1500mm | 2200kg | ||

| Weight for 2000mm | 2400kg | ||

Product Description

FAQ

1: Where is your company

A: Our company is located in Tengzhou City, Shandong Province.

2: What about your warranty?

A: Warranty is one year. During warranty time, if the parts are damaged because of Nonhuman factors, we will send new replaced parts for free

3: How do you offer after-sale service?

A: We usually offer technical support online by wechat or whatsapp. Customer describe the problems and send videos and pictures, our technician will help to solve the problems

4. What is your standard package?

A: Our package is export standard plywood case with pallet.

5: What's the Payment Terms?

A: T/T, 30% initial payment when order, 70% balance payment before shipment;

6: What's the MOQ?

A: 1 set.

PHONE