CJM320

The bench lathe has all the basic features of an ordinary large gear lathe and it has the unique advantages of small size, light weight and low noise. Its relatively simple construction also maintains complete rigidity and high strength hardened steel base construction.

In addition, a full set of accessories is provided for each bench lathe, these lathes are still capable of turning, drilling, boring, knurling and threading, it can be widely used for small metal/non-metal workpieces machining in home metal fabrication, technical school education or research in scientific facilities

The bench lathe has all the basic features of an ordinary large gear lathe and it has the unique advantages of small size, light weight and low noise. Its relatively simple construction also maintains complete rigidity and high strength hardened steel base construction.

In addition, a full set of accessories is provided for each bench lathe, these lathes are still capable of turning, drilling, boring, knurling and threading, it can be widely used for small metal/non-metal workpieces machining in home metal fabrication, technical school education or research in scientific facilities

Product Use

The bench lathe has all the basic features of an ordinary large gear lathe and it has the unique advantages of small size, light weight and low noise. Its relatively simple construction also maintains complete rigidity and high strength hardened steel base construction.

In addition, a full set of accessories is provided for each bench lathe, these lathes are still capable of turning, drilling, boring, knurling and threading, it can be widely used for small metal/non-metal workpieces machining in home metal fabrication, technical school education or research in scientific facilities"

Product Features

Most economical,widely useful hobby lathe.

Power longitudinal feed allows threading.

V-way a depot double triangle and rectangle side way.

Easy access to safety switches.

Spindle is supported by precision tapered roller bearing.

Head stock be gear drive power.

Large MT4 spindle bore.

High precision chuck.

Induction cuts with cross & longitudinal power feed

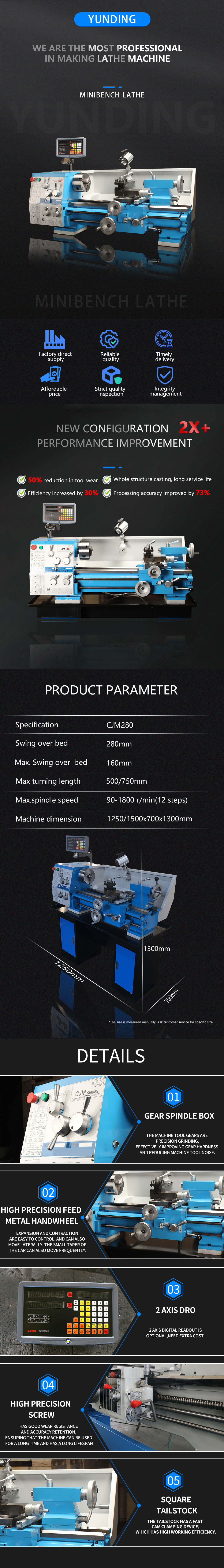

Gear Spindle Box

The Machine Tool Gears Are Precision Grinding, Effectivelyimproving Gear Hardness And Reducing Machine Tool Noise.

High Precision Feed Metal Handwheel

Expansion And Contraction Are Easy To Control,And Can Also Move Laterally. The Small Taper Of The Car Can Also Move Frequently.

2Axis Dro 2 Axis Digital Readout Is Optional,Need Extra Cost.

High Precision Screw Has Good Wear Resistance And Accuracy Retention,Ensuring That The Machine Can Be Used For A Long Time And Has A Long Lifespan

Square Tailstock

The Tailstock Has A Fast Cam Clamping Device,Which Has High Working Efficiency.

Product Parameters

| Specifications | Units | CJM320 |

| Lathe bed maximum turning diameter | mm | 320 |

| Skateboard largest work piece turning diameter | mm | 600/800 |

| Maximum work piece diameter rotary table | mm | 200 |

| Spindle hole diameter | mm | 38 |

| Taper of spindle | mm | No.5 |

| Spindle | mm | 80-1600r.p.m 12 |

| The maximum horizontal stroke of cutter | mm | 160 |

| The knife frame maximum longitudinal travel | mm | 100 |

| Processing metric thread number | mm | 22 |

| Processing range of metric threads | mm/r | 0.2-7 |

| The processing module thread number | mm/r | 21 |

| The processing module thread range | mm | 0.2-3.5 |

| Processing diameter pitch threads number | kg | 31 |

| Processing pitch thread range | mm | 8-120 1/n″ |

| Longitudinal feed spindle turret at every turn | mm | 0.1-1.4 |

| The transverse feed amount per turn spindle turret | mm | 0.045-0.6 |

| The maximum amount of movement of the tailstock sleeve | mm | 80 |

| Taper the tailstock sleeve | mm | No.3 |

| Electric machinery | w | 750W/380V/50HZ |

| Gross / net weight | kg | 450/390 |

| Dimensions (length * width * height) | mm | 1370×685×1360 |

| Packing size (length * width * height) | mm | 1470×770×1470 |

Product Description

FAQ

1:How can I choose the most suitable machines ? A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model You can also send us the products drawing ,we will choose the most suitable machines for you . 2: What's your main products of your company? A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on . 3: Where is our factory located? How can I visit there? A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us. 4. What is your trade terms? A : FOB, CFR and CIF all acceptable. 5: What's the Payment Terms ? A : T/T ,30% initial payment when order ,70% balance payment before shipment ; Irrevocable LC at sight . 5: What's the MOQ? A: 1 set .(Only some low cost machines will be more than 1 set ) We want to know: 1.What's your Industrial Voltage? 2.We strongly suggest you to tell us size, material of your workpiece for our evaluation, if possible, better to send us workpiece drawing, so that we can recommend you most suitable model! 3.If need CIF Price, please kindly tell us the port of destination.

PHONE