GMC2008

GM series CNC gantry machining center inherits the advantages of traditional gantry machine tools such as strong rigidity of the basic frame, symmetrical structure and good stability. By strengthening the reinforcement structure and reasonable layout, the whole machine is rigid. It has a variety of machining functions, such as chip milling, boring, drilling (expanding and reaming) and tapping.

It is widely used in various machining fields such as automotive, mold, aerospace, packaging, hardware, etc.

GM series CNC gantry machining center inherits the advantages of traditional gantry machine tools such as strong rigidity of the basic frame, symmetrical structure and good stability. By strengthening the reinforcement structure and reasonable layout, the whole machine is rigid. It has a variety of machining functions, such as chip milling, boring, drilling (expanding and reaming) and tapping.

It is widely used in various machining fields such as automotive, mold, aerospace, packaging, hardware, etc.

Applications:

GM series CNC gantry machining center inherits the advantages of traditional gantry machine tools such as strong rigidity of the basic frame, symmetrical structure and good stability. By strengthening the reinforcement structure and reasonable layout, the whole machine is rigid. It has a variety of machining functions, such as chip milling, boring, drilling (expanding and reaming) and tapping.

It is widely used in various machining fields such as automotive, mold, aerospace, packaging, hardware, etc.

Control System

Standard configuration: GSK

Optional: Siemens/Fanuc/Syntec/Mitsubishi

Automatic tool changer

Standard configuration: 24-tool cap magazine.

Shafts

Taiwan brand high quality spindle, VOLIS/OKADA/ROYAL/AIMACH

Standard Configuration:8000rpm

Optional configuration:10000/12000 rpm

Workbench

High-frequency quenching to improve hardness

3-axis linear guideway

Use high precision Taiwan or Japan brand, HIWIN/PMI/THK et

Screws

3-axis screws, using high-precision Taiwan or Japan brands, HIWIN/PMI/THK, etc.

Lubrication system

The invention can be used timely, quantitatively, accurately, efficiently, conveniently and reliably, which helps to improve the service life of the machine tool.

Pneumatic system

With electronic display for better stability, the air pressure will be very stable when changing tools on the machine and spindle, and there will be no tool jamming.

Electrical parts

Standard configuration: DELIX

Optional configuration: Siemens"

Standard configuration: Electric cabinet heat exchanger

Optional: Electric cabinet air conditioner

Product Parameters

| NO | parameter | GMC2008 |

| 1 | Number of machine coordinates (number of axes) | 3 |

| 2 | Coordinates (number of axes) can be controlled at the same time | 3 |

| 3 | Workbench size | 1700x700 |

| 4 | T-slot (width × number × spacing) | 18x6x100 |

| 5 | Maximum load weight | 1500 |

| 6 | X/Y/Z axis travel | 1500x760x700 |

| 7 | Distance from spindle end to worktable | 130-830 |

| 8 | Column spacing | 802 |

| 9 | Spindle taper | BT40 |

| 10 | Main motor power | 20/53 |

| 11 | Main motor torque | 126/250 |

| 12 | Spindle speed | 15000 |

| 13 | Fast movement speed (X/Y/Z) | twenty four |

| 14 | Cutting feed speed | 1-12000 |

| 15 | Tool magazine capacity | twenty four |

| 16 | Maximum tool length | 300 |

| 17 | Maximum tool diameter | Ø78 / Ø125 |

| 18 | Maximum tool weight | 8 |

| 19 | Positioning accuracy (X/Y/Z) | 0.008 |

| 20 | Repeat positioning accuracy (X/Y/Z) | 0.006 |

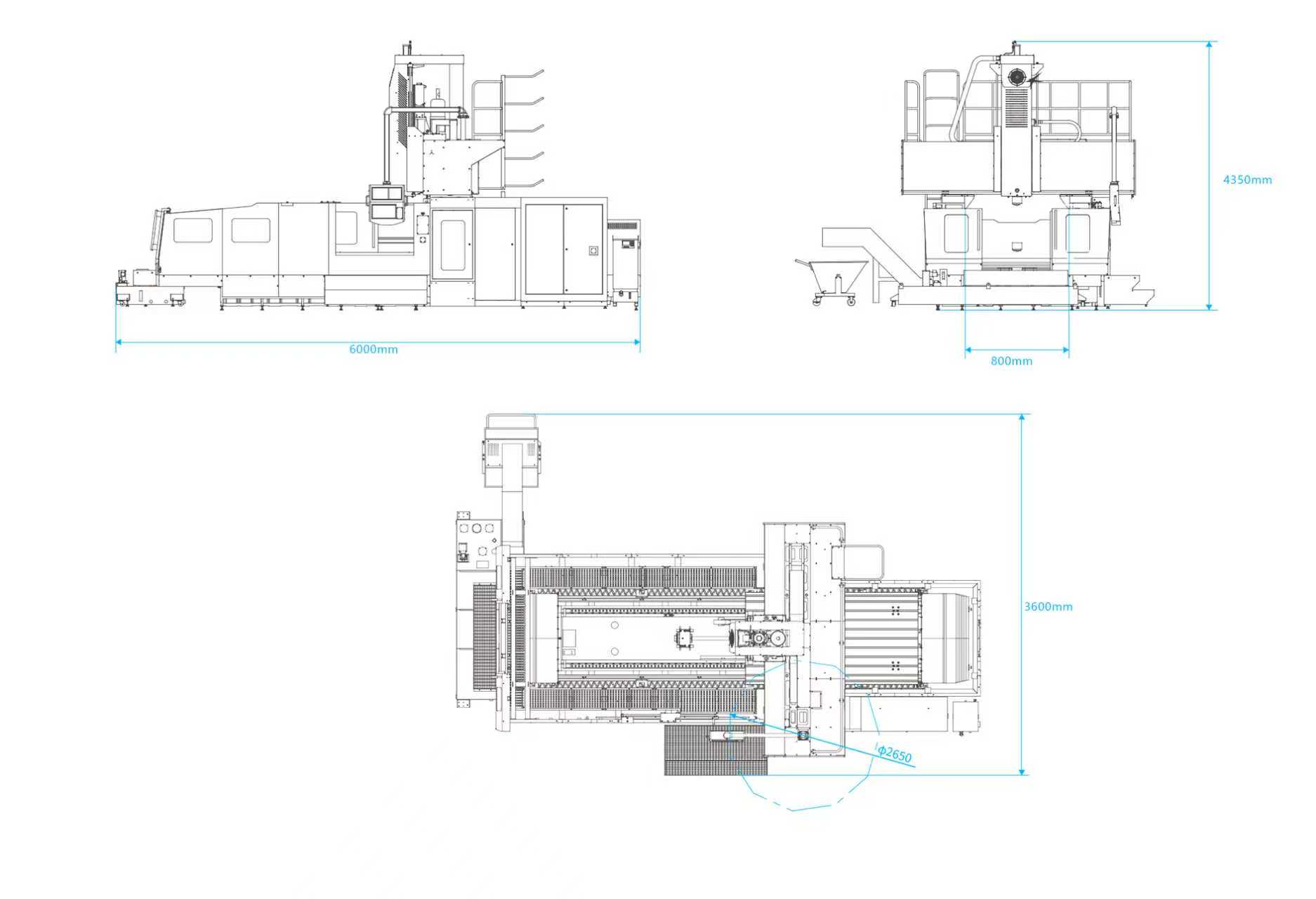

| 21 | Machine dimensions (length x width x height) | 6000x3600x4350 |

| 22 | Machine weight | 10000 |

Product Description

FAQ

1: Where is your company

A: Our company is located in Tengzhou City, Shandong Province.

2: What about your warranty?

A: Warranty is one year. During warranty time, if the parts are damaged because of Nonhuman factors, we will send new replaced parts for free

3: How do you offer after-sale service?

A: We usually offer technical support online by wechat or whatsapp. Customer describe the problems and send videos and pictures, our technician will help to solve the problems

4. What is your standard package?

A: Our package is export standard plywood case with pallet.

5: What's the Payment Terms?

A: T/T, 30% initial payment when order, 70% balance payment before shipment;

6: What's the MOQ?

A: 1 set.

PHONE