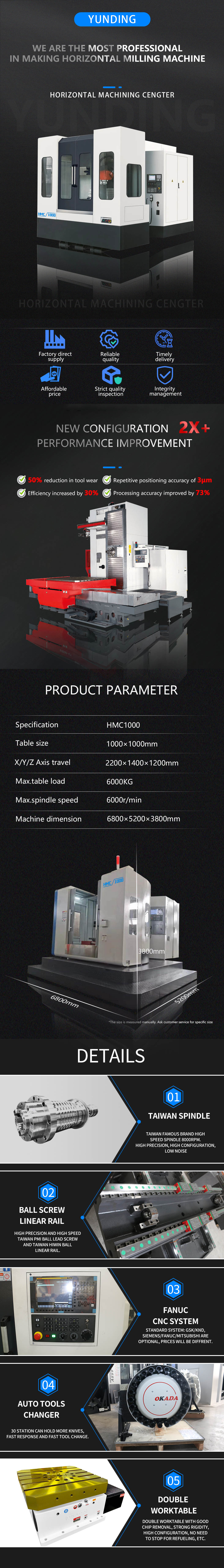

HMC1000

The HMC Series CNC Horizontal Machining Centers are ideal for the production of box and irregular workpieces for the automotive, shipbuilding, engine and general manufacturing industries.

The machines are high-performance, highly reliable and high-precision products characterized by compact construction and fast response time.

The HMC Series CNC Horizontal Machining Centers are ideal for the production of box and irregular workpieces for the automotive, shipbuilding, engine and general manufacturing industries.

The machines are high-performance, highly reliable and high-precision products characterized by compact construction and fast response time.

Applications:

The HMC Series CNC Horizontal Machining Centers are ideal for the production of box and irregular workpieces for the automotive, shipbuilding, engine and general manufacturing industries.

The machines are high-performance, highly reliable and high-precision products characterized by compact construction and fast response time.

Product features

Fixed column structure

CNC table, minimum 10, hydraulic clamping, suitable for heavy cutting.

Pneumatic-hydraulic conversion lifting and balancing device

Z-axis down to four rectangular hard rails; x-axis to overloaded roller type linear guideways; y-axis to rectangular hard rails

numerical control system

Standard configuration:FANUC 0i MD

Optional system: m7b/M70A Mitsubishi or Siemens 828D

Optional system:Auto chip system

Optional:CNC continuous indexing table(not suitable for heavy cutting)

Cutter

24 robotic tools

chain tool magazine

Spindle

high rigidity and high precision spindle unit

Product Parameters

| Model | HMC1000 | |

| X-axis travel | mm | 2200 |

| Y-axis travel | mm | 1400 |

| Z-axis travel | mm | 1200 |

| Table size | mm | 1000*1000 |

| Work table indexing | 1°*360 | |

| T slot size | mm | 125×22×6 |

| Max. Loading of work table | kg | 6000 |

| Spinlde center to table | mm | 350-1550 |

| Spindle nose to table surface | mm | 100-1300 |

| Spindle taper | BT-50 | |

| Spindle range | rpm | 6000 |

| Spindle power | kw | 15/18.5 |

| Cutting speed | mm/min | 1-8000 |

| X/Y/Z fast speed | mm/min | 24/24/24 |

| X/Y/Z posion accuracy | 0.015 | |

| Repeatability | 0.008 | |

| Positioning accuracy of B axis | +10" | |

| ATC | 24 pcs(optional 30pcs/40pcs 60pcs) | |

| Tool change time | S | 5 |

| Max. Tool weight | kg | 18 |

| Max. Dimeter of tool | mm | φ80/φ150 |

| Max. Lenght of tool | mm | 400mm |

| Maching weight | kg | 20000Kg |

| Machine dimention | mm | 6800×5200×3800mm |

Product Description

FAQ

1: Where is your company

A: Our company is located in Tengzhou City, Shandong Province.

2: What about your warranty?

A: Warranty is one year. During warranty time, if the parts are damaged because of Nonhuman factors, we will send new replaced parts for free

3: How do you offer after-sale service?

A: We usually offer technical support online by wechat or whatsapp. Customer describe the problems and send videos and pictures, our technician will help to solve the problems

4. What is your standard package?

A: Our package is export standard plywood case with pallet.

5: What's the Payment Terms?

A: T/T, 30% initial payment when order, 70% balance payment before shipment;

6: What's the MOQ?

A: 1 set.

PHONE